- January 09, 2026 10:33 am

- by Kevin

- January 09, 2026 10:33 am

- by Manek

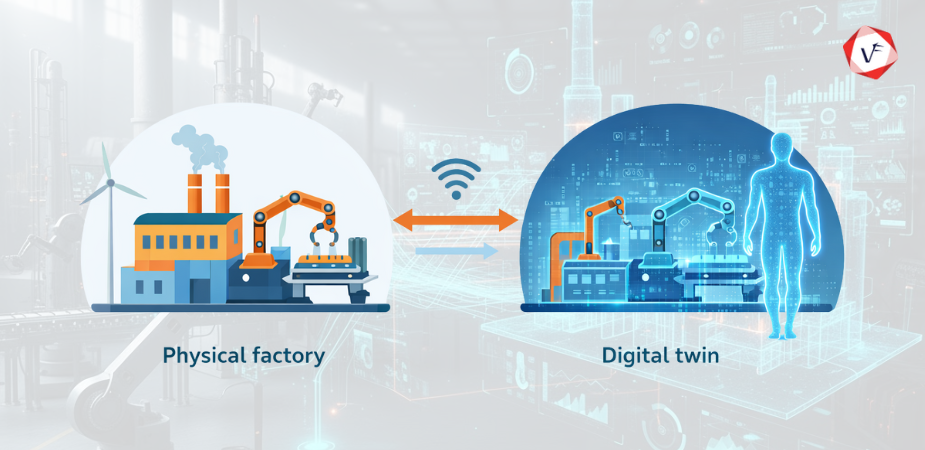

Manufacturing facilities, healthcare systems, and urban infrastructure share a common challenge: predicting failures before they occur and optimizing performance in real-time. Digital twin technology addresses this challenge by creating virtual replicas of physical assets, processes, or systems that update continuously with data from their real-world counterparts.

This technology bridges the gap between the physical and digital realms, enabling organizations to simulate scenarios, test hypotheses, and make informed decisions without disrupting actual operations. As industries increasingly rely on data-driven insights, digital twin technology has emerged as a transformative solution that enhances efficiency, reduces costs, and accelerates innovation across sectors ranging from aerospace to smart cities.

Understanding how digital twin technology functions and its applications provides valuable context for organizations seeking to leverage this powerful tool for operational excellence.

Digital twin technology creates a virtual representation of a physical object, system, or process that mirrors its real-world counterpart with remarkable precision. Unlike simple 3D models or simulations, a digital twin maintains a continuous connection to its physical equivalent through sensors, IoT devices, and data feeds.

This bidirectional relationship allows the virtual model to reflect changes in real-time while enabling users to test modifications in the digital environment before implementing them physically—eliminating costly trial-and-error in production environments.

The architecture of digital twin technology consists of three fundamental components:

Sensors embedded in the physical asset collect information about performance, condition, and environmental factors. This data streams to the virtual replica, where advanced algorithms process and analyze it to create an accurate digital representation. The system can then run simulations, predict outcomes, and provide insights that inform decision-making.

What distinguishes digital twin technology from traditional simulation tools is its ability to learn and adapt. Machine learning algorithms within the digital twin analyze historical data patterns and current operating conditions to improve predictions over time. This self-improving characteristic makes digital twin technology increasingly valuable as it accumulates more operational data.

Key differentiators include:

Digital twin technology has revolutionized operations across diverse sectors. Here's how different industries leverage virtual replicas to drive innovation and efficiency:

Digital twin technology has found widespread adoption in manufacturing, where companies use virtual replicas of production lines to optimize workflows, predict equipment failures, and test new configurations without halting operations.

Automotive manufacturers create digital twins of entire assembly lines to identify bottlenecks and improve throughput. These virtual models simulate different production scenarios, allowing engineers to determine the most efficient arrangements before making costly physical changes. The result is reduced downtime, improved quality control, and faster adaptation to new product requirements.

Manufacturing use cases:

The healthcare sector leverages digital twin technology to revolutionize patient care and medical research. Hospitals create digital twins of individual patients using medical imaging, genetic information, and health records. These personalized virtual models help physicians predict how specific treatments might affect a patient, enabling truly customized medical interventions.

Medical device manufacturers also use digital twin technology to test equipment performance under various conditions, ensuring reliability and safety before clinical deployment. This virtual testing reduces development time while improving device effectiveness and patient outcomes.

Healthcare applications:

City planners and administrators employ digital twin technology to build comprehensive models of entire cities. These urban digital twins integrate data from traffic sensors, utility systems, weather stations, and public services to provide a holistic view of city operations.

Administrators can simulate the impact of new infrastructure projects, optimize traffic flow, and improve emergency response planning. Singapore's Virtual Singapore project exemplifies how digital twin technology enables better urban management through data-driven decision-making, resulting in improved quality of life for residents and more sustainable city development.

Smart city implementations:

The energy sector uses digital twin technology to manage complex infrastructure like power plants, wind farms, and electrical grids. Energy companies create virtual replicas of turbines, generators, and distribution networks to monitor performance, predict maintenance needs, and optimize energy production.

These digital twins help balance supply and demand more effectively while reducing operational costs and minimizing downtime. In renewable energy, wind farm operators use digital twins to optimize turbine positioning and predict maintenance requirements, maximizing energy generation while extending equipment lifespan.

Energy industry benefits:

Implementing digital twin technology requires a robust infrastructure of sensors, connectivity, data storage, and analytical capabilities. Understanding these components is essential for successful deployment.

IoT sensors serve as the eyes and ears of the digital twin system, continuously monitoring parameters such as temperature, pressure, vibration, and performance metrics. These sensors must be reliable and capable of operating in challenging environments while transmitting data accurately.

Critical sensor requirements:

Cloud computing platforms provide the computational power and storage capacity necessary for digital twin technology to process vast amounts of data in real-time. The cloud infrastructure enables scalability, allowing organizations to expand their digital twin implementations as needs grow.

Edge computing complements cloud platforms by processing time-sensitive data closer to the source, reducing latency and enabling faster responses to critical situations. This hybrid approach balances the need for immediate action with comprehensive analytics.

Organizations must consolidate information from multiple sources, including legacy systems, new sensors, and external data feeds. APIs and middleware solutions facilitate this integration, ensuring that the digital twin receives accurate and timely information.

Data quality and consistency remain paramount, as the virtual model's accuracy depends entirely on the reliability of incoming data. Establishing robust data governance frameworks ensures information integrity throughout the system.

Integration best practices:

Analytics and visualization tools transform raw data into actionable insights. Digital twin technology platforms incorporate dashboards that display real-time status, historical trends, and predictive analytics.

Advanced visualization capabilities allow users to interact with the digital twin, exploring different scenarios and understanding complex relationships within the system. These interfaces make digital twin technology accessible to stakeholders across an organization, from engineers to executives, democratizing access to critical operational insights.

Organizations implementing digital twin technology realize significant operational and strategic advantages. Understanding these benefits helps justify investment and guide implementation priorities.

Organizations implementing digital twin technology report substantial improvements in operational efficiency. By monitoring equipment performance in real-time, companies can shift from reactive maintenance to predictive maintenance strategies.

Digital twins analyze performance patterns to identify potential failures before they occur, allowing maintenance teams to address issues during planned downtime rather than responding to unexpected breakdowns. This proactive approach reduces maintenance costs by up to thirty percent while increasing equipment availability and extending asset lifespan.

Digital twin technology dramatically shortens product development cycles. Engineers can test thousands of design variations virtually, identifying optimal configurations without building physical prototypes. This virtual testing reduces development costs and time-to-market while improving final product quality.

Aerospace companies, for example, use digital twin technology to simulate aircraft performance under various conditions, identifying potential issues before the first physical test flight. This approach has reduced development timelines by 25-40% while improving safety and performance.

Organizations create virtual replicas of equipment and facilities where employees can practice procedures and troubleshoot problems in a risk-free environment. These training simulations provide hands-on experience without the safety concerns or costs associated with training on actual equipment.

New employees become productive faster, and experienced workers can refine their skills on virtual models of new equipment before it arrives. This reduces training costs while improving workforce capabilities and safety outcomes.

Digital twin technology enhances collaboration across distributed teams. Stakeholders in different locations can access the same digital twin, examining issues, proposing solutions, and making decisions based on shared, real-time information.

This collaborative capability proves particularly valuable for global organizations managing assets across multiple sites or working with external partners and suppliers. Everyone works from the same source of truth, eliminating miscommunication and accelerating decision-making.

Quantifiable benefits organizations experience:

Despite its substantial benefits, digital twin technology implementation presents several challenges that organizations must address strategically.

Initial investment costs can be substantial, encompassing sensors, connectivity infrastructure, software platforms, and integration services. Organizations must carefully evaluate the ROI, considering factors like improved efficiency, reduced downtime, and enhanced decision-making capabilities.

The business case becomes stronger when digital twin technology addresses specific pain points or enables new revenue opportunities. Starting with pilot projects allows organizations to demonstrate value before committing to enterprise-wide implementations.

Digital twins contain detailed information about assets, processes, and operations that could be valuable to competitors or malicious actors. Organizations must implement robust cybersecurity measures, including encryption, access controls, and network segmentation.

Regular security audits and employee training help protect digital twin systems from unauthorized access and cyber threats. Compliance with industry regulations and data protection laws adds another layer of complexity that must be carefully managed.

Security best practices:

Digital twin technology requires expertise in multiple domains, including IoT, data analytics, cloud computing, and domain-specific knowledge about the physical assets being modeled. Organizations may need to invest in training existing staff or recruiting specialists with the necessary skills.

Building internal capabilities ensures long-term success and reduces dependence on external consultants. Partnerships with technology vendors and educational institutions can help bridge knowledge gaps during implementation phases.

Different vendors offer proprietary platforms with varying capabilities and data formats. The lack of universal standards can complicate integration and limit interoperability between systems. Industry groups are working to establish common frameworks, but organizations must currently navigate a fragmented ecosystem of solutions.

Selecting platforms that support open standards and provide robust APIs helps future-proof implementations and maintains flexibility as the technology evolves.

Digital twin technology continues to evolve rapidly, with emerging capabilities promising even greater value for organizations. Understanding these trends helps organizations plan strategic implementations.

The integration of digital twin technology with augmented reality (AR) and virtual reality (VR) creates immersive experiences for users. Technicians wearing AR glasses can view digital twin data overlaid on physical equipment, receiving real-time guidance for maintenance procedures.

VR environments allow remote experts to "walk through" facilities and equipment, troubleshooting issues without traveling to the site. These immersive technologies make digital twin information more accessible and actionable, particularly for complex systems requiring specialized expertise.

5G networks will significantly enhance digital twin technology capabilities by providing the bandwidth and low latency necessary for more sophisticated applications. Faster data transmission enables digital twins to process information from more sensors, update more frequently, and support more complex simulations.

The improved connectivity facilitates digital twin deployments in remote locations and mobile applications, expanding use cases to include autonomous vehicles, mobile robotics, and distributed infrastructure management.

Advanced artificial intelligence and machine learning algorithms will make digital twins increasingly autonomous and predictive. Future digital twins will not only monitor and analyze but also make recommendations and, in some cases, automatically implement optimizations without human intervention.

These intelligent systems will identify patterns and relationships that humans might miss, uncovering optimization opportunities and preventing failures with even greater accuracy.

Sustainability initiatives increasingly rely on digital twin technology to monitor and optimize resource consumption. Companies use digital twins to track energy usage, water consumption, and waste generation, identifying opportunities to reduce environmental impact.

Digital twin technology helps organizations achieve sustainability goals while maintaining operational efficiency and profitability. As environmental regulations tighten and stakeholder expectations grow, this capability becomes increasingly valuable.

Emerging applications include:

Digital twin technology represents a significant advancement in how organizations monitor, analyze, and optimize their assets and processes. By creating virtual replicas that mirror physical counterparts in real-time, this technology enables predictive maintenance, accelerates product development, and improves decision-making across industries.

While implementation challenges exist—including initial costs, security concerns, and skills requirements—the benefits of digital twin technology continue to drive adoption as organizations seek competitive advantages through data-driven insights. The technology's self-improving nature means that value compounds over time as systems accumulate more data and refine their predictions.

Organizations that successfully implement digital twin technology position themselves for sustainable competitive advantage. The ability to predict failures, optimize operations, and innovate faster creates measurable business value that justifies the investment required.

For businesses looking to implement digital twin solutions or integrate this technology into their operations, Vofox's software development and software testing services provide the expertise needed to build robust, scalable systems that deliver measurable results. Our team combines deep technical knowledge with industry experience to guide successful digital twin implementations.

Have a chat with us whenever you'd like to explore our offerings and discover how digital twin technology can transform your operations.

Digital twin technology creates a virtual representation of a physical object, system, or process that maintains a continuous connection to its real-world counterpart through sensors and IoT devices. Unlike simple simulations, digital twins update in real-time, use machine learning to predict outcomes, and enable users to test changes virtually before implementing them physically.

While 3D models are static representations and simulations run predetermined scenarios, digital twins maintain a bidirectional, real-time connection with physical assets through continuous data feeds. Digital twins learn and adapt using machine learning algorithms, becoming more accurate over time as they accumulate operational data and can control or influence their physical counterparts.

Digital twin technology is widely used in manufacturing, healthcare, urban planning, energy, aerospace, automotive, and construction. Any industry with complex physical assets, processes, or systems can benefit from virtual replicas that enable predictive maintenance, optimization, and scenario testing. The technology is particularly valuable where downtime is costly or safety is critical.

Key benefits include predictive maintenance that reduces costs by up to 30%, accelerated product development through virtual testing (25-40% faster cycles), 50% reduction in unplanned downtime, improved operational efficiency (20-30% improvement), enhanced training capabilities, and better decision-making through real-time data insights and scenario simulation.

Main challenges include substantial initial investment costs for sensors and infrastructure, data security and privacy concerns requiring robust cybersecurity measures, the need for specialized expertise across IoT, analytics, and domain knowledge, and lack of industry standardization. Organizations must also ensure data quality, system integration, and clear ROI justification.

Costs vary widely based on scope and complexity, ranging from tens of thousands for simple applications to millions for enterprise-wide implementations. Factors include number of sensors, infrastructure requirements, software licensing, integration complexity, and ongoing maintenance. Starting with pilot projects helps organizations demonstrate value and build business cases for larger investments.

Yes, cloud-based platforms and subscription models have made digital twin technology accessible to small businesses. Organizations can start with focused applications targeting specific assets or processes, then expand as they realize benefits. Many vendors offer scalable solutions that grow with business needs without requiring massive upfront investments.

The future includes integration with AR/VR for immersive experiences, enhanced capabilities through 5G networks enabling more sensors and faster updates, advanced AI making systems increasingly autonomous, and growing use in sustainability initiatives. Digital twins will become more intelligent, predictive, and capable of autonomous optimization with minimal human intervention.

Guaranteed Response within One Business Day!

What is Infrastructure as Code (IaC)?

Front-End Performance in 2026: What Core Web Vitals Actually Mean for Your Site

What is FinOps?

Micro-Frontends: Breaking Down Monolithic React Applications

.png)

Zero-Trust Security Models for SaaS: What You Need to Know